The Mysterious, Murky Story Behind Soy-Sauce Packets

How Chinese takeout, a Jewish businessman from the Bronx, and NASA-approved packaging have shaped the 50-year reign of a well-loved American condiment

But as ubiquitous as soy-sauce packets are, no one knows where they first came from. The major players in the to-go soy-sauce industry today—KariOut and W Y Industries—don’t claim to have created the packet. Some have attributed the design to Ben Eisenstadt—the founder of the sugar-substitute manufacturer Sweet’N Low and the designer of his company’s trademark bubblegum-pink packets—but that connection remains unconfirmed.

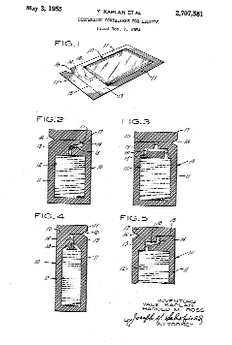

The first sign of a soy-sauce packet that resembles the one popular today is a 1955 patent, filed by two men named Harold M. Ross and Yale Kaplan, that outlines a “dispensing container for liquids.” The packet would hold “a single serving” of “sauce or syrup,” which could be extracted with a squeeze.

Ross and Kaplan's 1955 patent for a

"dispensing container for liquids" (United

States Patent and Trademark Office)

"dispensing container for liquids" (United

States Patent and Trademark Office)

But a key feature of Ross and Kaplan’s design that differs from soy sauce packets today is that “the flow of fluid will stop and any possible leakage will be prevented” as soon as the pressure is released. As anyone who has stained his or her shirt with errant soy sauce can attest, the brown, salty liquid isn’t nearly viscous enough for this to hold true; Ross and Kaplan’s brainchild was much better suited to ketchup.

From this vantage, soy-sauce packets appear not to be optimized for the substance they contain—a substance that, it should be noted, isn’t even technically soy sauce. Packaged soy sauce is often a cocktail of processed ingredients that resemble the real thing: water, salt, food coloring, corn syrup, MSG, and preservatives. But soy sauce, strictly defined, refers to a fermented combination of soybeans and wheat whose earliest direct predecessor was first mentioned in writing in the year 160. (Less-direct ancestors of modern-day soy sauce existed in China as far back as about 3,000 years ago.)

In the millennia since, arguments have brewed over what exactly constituted soy sauce. William Shurtleff and Akiko Aoyagi trace these disputes in their bookHistory of Soy Sauce (160 CE to 2012). The manufacturers of traditional fermented soybean paste at one point banded together and, through a proposal authorized by the Japanese government, contested the right of companies such as La Choy and Kari-Out to call their products soy sauce. These old-school outfits outlined an elaborate classification system for varieties of the product. In the end, it was too hopeful, and the proposal was withdrawn in 2005.

* * *

Even though the soy-sauce packet’s origin is an unsolved mystery, the story of how it became popular is not. That’s the story of Howard Epstein, who, as the founder of the dominant soy-sauce brand Kari-Out, is seen as the ambassador of packaged American soy sauce.Epstein became interested in food packaging because his father manufactured the long, flimsy plastic packaging for freezer pops. Epstein's first venture into his father’s trade was a popcorn-packaging business, which he bought for $5,000 over 50 years ago.

That business failed to gain traction, and Epstein, now 81, was looking for a change when one of his father’s salesmen, who sold tea bags, suggested he consider the soy-sauce-packaging business. In 1964, Epstein founded Kari-Out, and he says he arrived to the industry right as it was becoming commercially viable. He ran his new business out of the popcorn factory he owned.

At first, Epstein was regarded with suspicion, primarily because he, a Jew from the Bronx, was different from most people in the industry. “No one trusted me because it was the old times. The Chinese ran the business,” Epstein says. His attempts to sell his packets to wholesalers were met with apathy and even cold-shouldered silence. “I had one potential customer,” he says. “I went in and asked him if he would be interested in selling my soy sauce. He didn’t speak. He never talked to me.”

But Epstein persisted, and his familiarity with freezer-pop packaging proved helpful in solving the problems with soy-sauce packets at the time: They leaked and they were too flimsy. “The only difference is a freezer pop has a much longer bag,” Epstein says.

Epstein’s break came in the form of affordable air travel, which went mainstream in the 1970s. To serve the newly airborne hordes of families and businessmen, airlines began offering prepared foods onboard. Epstein found his first major foothold as the primary provider of soy sauce for these in-flight meals.

Cheap airfare also allowed Epstein to travel the country in search of new customers. He was scouting at a time when Chinese takeout joints were becoming as commonplace as nail salons and convenience stores in strip malls around the country. “Chinese business was growing at this time because China was not as business-friendly,” he says. “People were leaving China and coming into the United States to open a restaurant and cook. The industry was booming.”

He soon built up a widespread network of customers, and Kari-Out’s products appeared in the Chinese restaurants across the country. Now, he estimates that Kari-Out has a 50 percent market share. The company’s soy-sauce packets remain ubiquitous—Epstein recalls finding Kari-Out packets at a concession stand in rural Iceland a couple years ago. “We’ve survived 50 years,” Epstein says. “I never get sick of Chinese food or soy sauce.”

* * *

But has the American public gotten sick of soy sauce packets? Sometimes they squirt their contents in unintended directions, and they’re fairly wasteful, often dispensing too much sauce, or not enough. But in the more than 50 years that they’ve been around, little has been done to change their design.Reinventing a condiment package with decades of cultural inertia is difficult, but it has been done before. H.J. Heinz Company upgraded its traditional ketchup packets—the tear-at-the-corner annoyances that invariably produce messes and yield too little sauce—by hiring an industrial design firm to think about alternate sauce-delivery mechanisms. They came up with the Dip & Squeeze, a small plastic tub that can be opened fully from the side and dipped in, or opened partially from the top and squeezed out cleanly.

Can soy-sauce packets be made better too? Gary Murphy thinks so. Murphy, the founder and CEO of Little Soya, is an unlikely soy-sauce pioneer with a loud laugh. A Texan, he has built up a business reselling Chinese furniture in America and once owned a legal courier company in Houston. Even when Murphy started working as a food-services consultant, soy sauce was plain and ignorable—just another nuisance to deal with when eating late-night Chinese takeout on the road.

His perspective changed when, in 2008, he was approached by Jeffrey Frederick, who helps oversee the food and beverages served at Caesars Palace in Las Vegas. Frederick wasn’t satisfied with the soy sauce being served at the casino's buffets—he deemed it too salty, too metallic-tasting, and lacking in the rich, savory dimension of flavor known as umami—and its disposable packaging bothered him as well. When Murphy, at Frederick's request, sought out a more natural, authentic, and sustainable alternative, he found nothing. So he set out to make his own.

On top of his packed work schedule, Murphy went to grocery stores near and far, buying bottles of soy sauce to taste, sniff, and swish about. He’d prowl aisles for hours—“People would get suspicious of me," he says—and study the products’ packaging and ingredients.

What Murphy found was that the market was concentrated among a few Japanese brands, such as Kikkoman, which all produced a similar brown liquid that has come to symbolize soy sauce in the U.S. Murphy says that American soy sauce is sweeter than Asian soy sauces, which leads to the metallic taste that many complain about. He says his sauce corrects this, and is gluten-free to boot. (While this fact may play into American food trends, it’s worth noting just how far a departure gluten-free soy sauce is from the fermented wheat paste of yore.)

But the most interesting feature of Murphy’s work for Little Soya is the packaging that Frederick requested—the first meaningful improvement on the classic disposable soy-sauce packet. Where the soy-sauce packet is straightforward and defined by right angles, Little Soya’s packaging, which was modeled on existing packaging from other parts of the world, is quirky, rounded, and efficient. It is a small translucent plastic fish whose mouth puckers into a bright green cap, which can be screwed back on to save any unused sauce for later.

The market presence of Little Soya's upscale, diet-trend-friendly sauce plays into an industry-wide rise in production of premium condiments. A report put out by the market-research firm Euromonitor International last November stated that even as the economy has recovered, many Americans still elect to eat at home, but now seek out high-end sauces and condiments to replicate the experience of eating at a restaurant. Sales of high-priced barbecue sauce, salad dressing, and soy sauce are seeing large gains as a result; Little Soya, while still small, now brings in about $1 million in revenue per year.

The cap proved useful in another, more unexpected context, too. After hearing that astronauts complained about the messiness of using traditional soy-sauce packets in space, Murphy provided NASA with some of Little Soya's fish. While the fish might be the long-awaited soy-sauce solution here on earth, mainstream soy sauce still isn't fully optimized for interstellar travel—Murphy had to boost the flavors in the NASA batch because space turns people into less-sensitive tasters.

No comments:

Post a Comment